Cost Optimization for Line Haul Transportation of 3PL Players

Faculty Contributor : L. S. Murty, Professor

Student Contributors : Isha Dhiman and Nitin K. V.

Line haul transportation is a key aspect of the operations of 3PL players in India’s growing logistics industry. Inflexible schedules and constant pressure from suppliers and customers necessitate innovative cost reduction measures. This study identifies the variable cost component of the truck pricing and demonstrates the cost saving achieved by providing flexibility through transportation scheduling. The study is based on TVS Logistics Services Limited.

TVS Logistics Services Limited is a 3PL (Third-party logistics) company, primarily catering to the automotive industry. Their inbound logistics deals with the collection of consignments (forgings and auto-components) from the suppliers and delivering them to customers (Ford, Tata Motors etc.). Collection and delivery is according to the schedule given by these customers. We will now look at the operations of the company in detail.

Operational Details

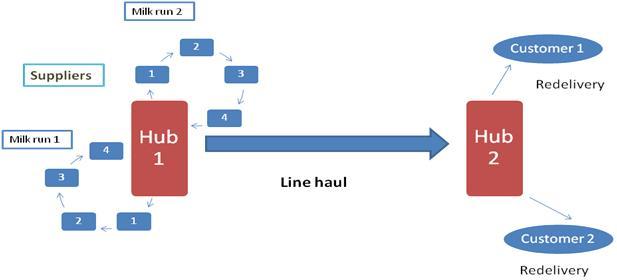

The inbound operational details, as studied in a field visit to the Hosur hub of TVS Logistics, are depicted in Exhibit 1.

Exhibit 1 Inbound operations of TVS Logistics

Exhibit 1 Inbound operations of TVS Logistics

Milk Run

Milk run process is used for collection of parts or automotive components from various suppliers in the nearby region. The material or parts data is collected from the suppliers on a daily basis. A trip sheet is prepared for each vehicle for a particular day which lists the suppliers, the route and sequence of collection to be followed and a window time for reaching a particular supplier. A cargo way bill is also generated which is given to the vehicle operator which consists the description of parts, quantity etc. The components which are collected through the milk-run operation are then segregated according to the different supplier items and loaded on separate trucks for line haul.

Line Haul

The parts or automotive components which are collected in the hubs have to be sent to the respective hubs near the customers’ manufacturing locations. So, planning and loading of components is done for different locations in different trucks.

Line haul operations account for the major part of the transportation for a part. The cost of transporting from supplier to hub, or from hub to customer is less than the transport from hub to hub. In addition, line haul operations require multi axle vehicles and these vehicles which are obtained in the market at spot rates. There was no provision to source the trucks on a constant rate basis, and no option to get a contract on the price of trucks. The only option was to have a contract for the number of trucks. TVS Logistics has to accept the price of the trucks.

Re-Delivery

The Re-delivery operation involves sending out the supplies collected at the hubs to the customers as per the schedule given by the customers. The material collected from the suppliers is segregated for each customer and then sent to respective customers as indicated by the schedule.

Cost Cutting Challenges

Based on the findings and the understanding of the operations of TVS Logistics warehouse, the following aspects were identified as having potential for improvement.

-

Optimization of Fleet – Till now only manual planning is done for route selection for the fleet, both for milk-run and line haul operation. Some mechanism or algorithm has to be identified for having an optimised schedule.

-

There is a choice between allocating warehouse space between different hubs and allocating warehouse space in a single hub. Allocating warehouse space in multiple hubs for a single customer might actually help reduce the number of trips in between the hubs.

-

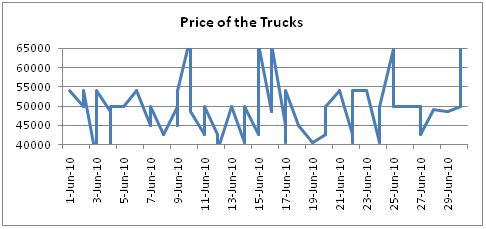

As the demand for automotive components increase during the latter half of the month, the availability of the trucks become problematic during this time. Due to the uneven demand pattern, the price of the trucks is decided by the transporters daily and there is a huge variation between the prices on different days. Due to this variability and skewed demand pattern, the costs of transportation are also high. The price variability of the trucks has been illustrated in Exhibit 2.

Exhibit 2 Variation in the price of trucks

Exhibit 2 Variation in the price of trucks

-

Rate Differential- It is also seen that there is a rate difference between the to and fro costs from one hub to another, i.e. transport rates depend on the point of origin and destination of the freight. For example, if the truck goes from Pune to Chennai the price charged is more than that if it goes from Chennai to Pune.

-

Return Load- The company provides the material and pays only for one side transportation of the truck during line haul. It is not responsible for the return load. The return trip load is left to the transporter.

Options considered

After considering the challenges faced by TVS logistics observed through the visit to the Hosur hub and discussions with the top management, we decided to focus on the following objectives for the project.

-

To reduce the total cost of operations for TVS logistics by optimizing the material transportation

-

To determine the type and number of trucks to be used for delivery

-

To minimize the hub to hub transportation cost of line haul operations.

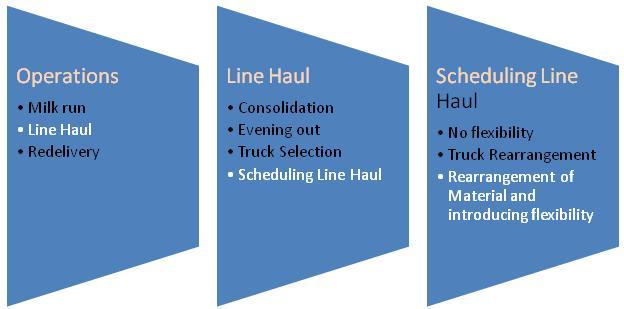

Our approach to attain these objectives is illustrated in Exhibit 3. Due to the uneven demand pattern, the price of the trucks is decided by the transporters daily and hence, there is a huge variability. It has also been observed that TVS Logistics has to send the material sourced from suppliers on a particular day to the customer on the same day. Delivery schedule is not flexible. The project focuses on these aspects to reduce the cost of operations.

Exhibit 3 Approach to the final solution

Exhibit 3 Approach to the final solution

Solution

TVS logistics is operating with zero inventory and no gaps in the transition period. The project solution suggests incorporating a time window in the transition period and mitigating the rigid requirement of sending the material on the same day as it is sourced.

If a two-day window is provided, then TVS logistics will have ample time not only to plan, but also to decide when to send the material and what material to send in what type of truck. This decision will be taken mainly by keeping in mind the price of the trucks on that particular day. The schedule given to the TVS logistics will be the same schedule as given before except for a few changes:

-

The schedule is given two days early to TVS logistics

-

The same schedule is not given to both TVS logistics and suppliers

-

The schedule given to TVS logistics is the same as before, detailing the amount of material that has to be sent before a particular day so that it reaches the destination hub in time to satisfy the requirement of the customer

-

The schedule given to the supplier is shifted ahead by two days so that the material that has to be sent on i+2th day is collected on ith day itself. Then the material can be sent on day i, or day i+1, or at maximum by day i+2

-

The window can be of one day or three days depending on the profitability of the model. Whichever time window gives a better profit margin, that time window can be adopted

We have formulated the model on four levels.

-

First level looks at only weight allocation to the trucks given a time window of 2 days

-

Second level utilizes both weight and volume allocation to trucks given a time window of 2 days

-

Third level looks at package level data, and can help determine which package to send, when it is to be sent and by which truck it has to be sent given a time window of 2 days

-

The fourth level builds upon the third level for introducing a variable time window model

The second model gives a clear understanding of the approach followed and has been further discussed in detail.

Theoretical Model

We consider the weight and volume of the material to be transported while doing the optimization of the line haul operations. Here also we consider one lane i.e. a path between two hubs for transportation of material. In this model we consider

-

One week period of transfer of material i.e. day 1 to 7

-

No division of material according to the type or consignment number

-

Both material weight as well as volume

-

Different types of trucks

-

Variation in the price of the trucks

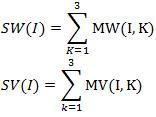

Mathematically, the model can be represented as follows:

Variables

The key variables considered are:

-

I – The day of the week - 1,2,3,4,5,6,7

-

J – Type of truck, 1-Container, 2-Tools

-

K- Day on which material is sent 1-Same day, 2-one day later, 3-Two days later

-

Z- Cost of Transportation

-

SW(I)- The sourced material weight from suppliers at a hub on Ith day.

-

SV(I)- The sourced material volume from suppliers at a hub on Ith day.

-

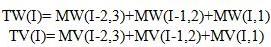

TW(I)- The sent material weight from a hub to another hub on Ith day.

-

TV(I)- The sent material volume from a hub to another hub on Ith day.

-

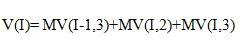

V(I)- Inventory of material on Ith day based on volume.

-

MW(I,K)- The weight of material sourced on Ith day and sent on Kth day from a hub.

-

MV(I,K)- The volume of material sourced on Ith day and sent on Kth day from a hub.

-

CW(J)- The weight carrying capacity of the truck of type J.

-

CV(J)- The volume carrying capacity of the truck of type J.

-

P(J,I)- The price of the truck of type J on Ith day.

-

N(J,I)- The number of trucks of type J sent on Ith day.

Constant

SC - Storage cost of a warehouse in the hub

Constraints

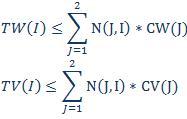

Capacity Constraint: The total material to be sent has to be less that the total weight and volumetric capacity of the chosen number of trucks of a particular type sent on a day.

Other Constraints

-

The material sourced on a particular day has to be sent either on the same day, day later or two days later. Thus,

-

The material sent today should include the material sourced two days, one day before as well as the material sourced today. Thus,

-

The inventory left has to be the material sourced one day before, sent two days later and sourced on the same day which is to be sent the next day and day after. Mathematically,

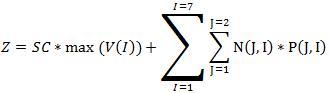

Objective Function

The objective of the optimization problem is to minimize the cost of line haul by optimum allocation of material and using minimum number of trucks according to price uncertainties.

Thus,

This will give the total minimized cost considering the inventory left and the weight as well as volume of the material and will calculate the required number of trucks.

Evaluation of the solution is through linear programming models, developed to determine the delivery schedule of the material collected from suppliers. The model is validated with the help of the data provided by the TVS Logistics for the Gurgaon Hub operations for a typical month.

The model validation gives a cost saving of 1.46% for the line haul operations (two day window) and an annual savings of ~13.46 lakh per hub per year.

Conclusion

This model reduces the transportation cost but increases the storage cost. Even though the approach adds inventory to the supply chain, this case shows a cost saving because of the variation in the truck price and the opportunity to consolidate. This method opens up potential avenues for TVS Logistics for further cost reduction such as planning return trips, having contracts for truck sourcing and pricing instead of relying on the spot market.

Keywords

Operations, Logistics, Transportation, Line Haul, Truck Sourcing, Cost Reduction, Material Scheduling

Contributors

L.S.Murty is a Professor in the Productions and Operations Management Area at Indian Institute of Management, Bangalore. He has a fellowship from Indian Institute of Management, Ahmedabad, India (1987) and a Bachelor of Technology degree from Jawaharlal Nehru Technological University, India (1978). He can be reached at

lsmurty@iimb.ernet.in

Isha Dhiman (PGP 2009-11) holds a Bachelor's Degree in Electronics and Communication Engineering from Ambala College of Engineering, Ambala, India. She can be reached at

isha.dhiman09@iimb.ernet.in

Nitin K V (PGP 2009-11) holds a Bachelor's Degree in Electronics and Communication Engineering from NIT Kurukshetra, India. He can be reached at

nitin.v09@iimb.ernet.in

References

-

Current Status of Logistics In India, G Vaidyanathan,PIANC Magazine, Feb 2007

-

The Logistics Sector in India, Overview and Challenges by Pankaj Chandra and Nimit Jain, March 2007

-

Trade and Logistics: An East Asian Perspective, Robin, Jitendra-World Bank, David- Purdue University

-

Determining the Most Effective Startegy for Multinational Companies to Enter the Indian Road Freight Market, Sarah Tatrallyay, IIM Bangalore, November 2009

-

Emerging Trends in Third Party Logistics in Indian Auto Industry, Akshay Singh, SP Preethi, IIM Bangalore, August 2009

-

Roadmap for Logistics Excellence :Need to break the unholy equilibrium, G Raghuram, Janat Shah, CII Logistics Convention, Chennai, October 2003

-

http://www.cscmpindia.com/Events/20112003/3.PDF, 3PL Challenges in India, Dr. B.S. Sahay, last accessed on August 15, 2010

-

http://www.tvslogisticsservices.com/the-company.asp, About us, TVS Logistics Website, last accessed on August 15, 2010

-

GAMS – A user’s guide, Tutorial by Rosenthal